B68M-P18-KV-RC1

INSULATED HYDRAULIC PUMP, BATTERY POWERED, RADIO CONTROLLED, 700 bar

![Type C [EU]](https://cdn.cembre.com/img/99175087-44f2-4171-9db5-becd34fe6a71/ico_plugEU.png?fm=jpg&q=80&fit=max&crop=124%2C125%2C0%2C0)

Gallery

B68M-P18-KV-RC1

INSULATED HYDRAULIC PUMP, BATTERY POWERED, RADIO CONTROLLED, 700 bar

![Type C [EU]](https://cdn.cembre.com/img/99175087-44f2-4171-9db5-becd34fe6a71/ico_plugEU.png?fm=jpg&q=80&fit=max&crop=124%2C125%2C0%2C0)

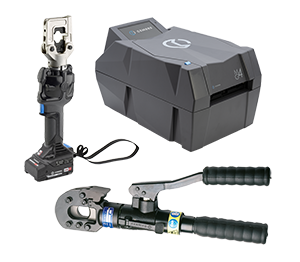

Included into package

-

CVB-031: --

-

ASC55-EU: --

-

ASC55-UK: --

-

ASC55-USA/CA: --

-

ASC55-AUS/NZ: --

Description

The B68M-P18-KV-RC1 cordless insulated electro-oleodynamic pump exerts pressure up to 700 bar independently, releasable at any time and in complete safety by means of the special button.

It is equipped with a two-speed hydraulic system to make operation more agile and rapid, and is complete with type I38-F automatic locking female quick coupler for connecting insulated oil flexible hoses.

This pump is equipped with a convenient push-button on board machine for easy actuation and release of hydraulic pressure. Alternatively, a convenient radio-controlled push-button panel is available to perform complex operations in confined spaces such as manholes and sumps from a safe distance. An optical-acoustic warning allows verification of each stage of execution.

Quiet and easy to handle, this pump has a solid, compact design to withstand any stress and features an ergonomic handle to ensure high levels of comfort even with prolonged use.

For added safety, it features a pressure relief valve, a quick pressure release button, and a protected run button to prevent accidental operation.

The pump features the OLED display to monitor various parameters in real time.

To enhance the user experience, the pump is equipped with an automatic rechargeable battery docking system with control button.

SMARTOOL technology allows viewing and downloading of recorded data, ensuring complete digital support.

Read all

Close

Features

Range of operating temperature

-15 ÷ 50 °C

Supply voltage

18 V

Pressure control system

EPS (electronic pressure sensor)

Main power connection

type C

Depressurizing

Smart Release Technology; manual; Smart Release Technology; manual

Insulated

Yes

Power supply

Electrical motor (battery)

Display

Yes

Net weight in operation

6 kg

Dimensions

406x236x212 mm

Unit in minimal packaging

1 PCE

Unit in standard packaging

1 PCE

Customs code

84135080

Ingress Protection

IP20

Supply configuration

2 x CB1880L battery; ASC55-EU battery charger; RRC1 remote controller; USB cable; shoulder strap; CVB-031 canvas bag

Does your Cembre Product need maintenance?

Fill in the form and follow the instructions to request the maintenance service for your product

Follow us

Subscribe to CEMBRE newsletter and stay tuned

Thank you, your request has been send successfully

You'll be contact soon by our commercial staff

Print label service

Fill in the form and follow the instructions to request the label print service

Thank you, your request has been send successfully

You'll be contact soon by our commercial staff

Does your Cembre Product need maintenance?

Fill in the form and follow the instructions to request the maintenance service for your product

Your maintenance request has been sent successfully

The next steps to complete the maintenance request:

- Print the form

- Send the package to your chosen CEMBRE retailer

Important: Do not insert batteries for safety reasons. Remember to include all accessories