RHU1000

HYDRAULIC CRIMPING HEAD, 1100 kN

Gallery

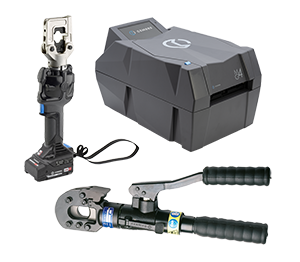

RHU1000

HYDRAULIC CRIMPING HEAD, 1100 kN

Included into package

-

VAL-1000: --

Certifications & approvals

-

CE

CE -

UKCA

UKCA

Description

The RHU1000 hydraulic crimping head is the ideal choice for installing connectors for full traction, transmission, and substations. Complete with a quick-connect male coupling with automatic locking, the RHU1000 guarantees high performance and ease of use even in the most demanding operations.

Main features:

Read all

Close

Main features:

- Compression force: 1100 kN (123 tons).

- Can be used in both single-acting and double-acting versions.

- Compatible with standard 1100 kN (123 tons) dies.

- Compatible with interchangeable Cembre dies and other standard systems.

- Removable die support for easy positioning of connectors.

- The upper part of the support rotates automatically during die change.

- Quick male coupling with automatic locking.

Features

Nominal crimping force

1100 kN

Range of operating temperature

-15 ÷ 50 °C

Crimping geometry

hexagonal; Circular; indent

Head shape

U shape without pin

Dimensions

414x278x185 mm

Unit in minimal packaging

1 PCE

Unit in standard packaging

1 PCE

Customs code

84679900

Does your Cembre Product need maintenance?

Fill in the form and follow the instructions to request the maintenance service for your product

Follow us

Subscribe to CEMBRE newsletter and stay tuned

Thank you, your request has been send successfully

You'll be contact soon by our commercial staff

Print label service

Fill in the form and follow the instructions to request the label print service

Thank you, your request has been send successfully

You'll be contact soon by our commercial staff

Does your Cembre Product need maintenance?

Fill in the form and follow the instructions to request the maintenance service for your product

Your maintenance request has been sent successfully

The next steps to complete the maintenance request:

- Print the form

- Send the package to your chosen CEMBRE retailer

Important: Do not insert batteries for safety reasons. Remember to include all accessories