B1300TEP

BATTERY HYDRAULIC TOOL FOR RAIL WEB ELECTRICAL CONNECTION

Gallery

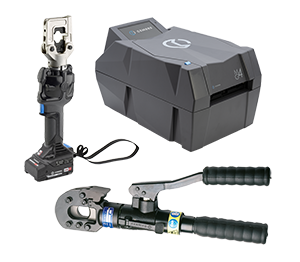

B1300TEP

BATTERY HYDRAULIC TOOL FOR RAIL WEB ELECTRICAL CONNECTION

Included into package

-

ASC55-EU: --

-

CB1852L: LI-ION BATTERY

-

OG13.2: PLUNGER

-

CAL19.20: GAUGE

Certifications & approvals

-

CE

CE -

UKCA

UKCA

Description

B1300TEP 电池驱动液压工具适用于挤压 AR60 型电气触头。

它配备一条 90 厘米长的高压软管,配有自动锁定的公母快速接头,用于连接 RHTEP 液压头(用于挤压触头)、RHC131(用于压紧连接器)和 TC025(用于切割电缆和电线)。泄压阀可控制操作的执行,以确保更大的安全性。

该工具配备了 CAL19.20 测量仪,用于控制导轨柄的钻孔和将校准过的鼻模拧到机头上,还配备了一个直径为 38 毫米的垫圈,适用于挤压 AR260 双触头。

B1300TEP 挤压工具安静且易于操作,设计坚固紧凑,可承受任何压力,配备符合人体工程学的手柄,即使长时间使用也能确保高度的舒适性。LED 灯照亮工作区域。

为了提高用户体验,该工具配备了带控制按钮的自动充电电池耦合系统。

SMARTOOL 技术可显示和下载记录的数据,提供全面的数字支持。

Read all

Close

Features

使用温度范围

-15 ÷ 50

电源电压

18

压力控制系统

max pressure valve

电网连接

type C

泄压

手动

管长

900 mm

动力供应

electrical motor (battery)

作业净重

5.7 kg

方面

354x239x103 mm

最大尺寸

354x239x103 mm

最小包装单元

1 PCE

标准包装单位

1 PCE

海关编码

84672920

Does your Cembre Product need maintenance?

Fill in the form and follow the instructions to request the maintenance service for your product

Follow us

Subscribe to CEMBRE newsletter and stay tuned

Thank you, your request has been send successfully

You'll be contact soon by our commercial staff

Print label service

Fill in the form and follow the instructions to request the label print service

Thank you, your request has been send successfully

You'll be contact soon by our commercial staff

Does your Cembre Product need maintenance?

Fill in the form and follow the instructions to request the maintenance service for your product

Your maintenance request has been sent successfully

The next steps to complete the maintenance request:

- Print the form

- Send the package to your chosen CEMBRE retailer

Important: Do not insert batteries for safety reasons. Remember to include all accessories

View more

View more

products ()

news ()

corporate ()

results

for

results

for

No results

Can't find results with these keywords

View Cembre group website

cembre.com

Look at products catalog

products.cembre.com

Log into Cembre group reserved area

my.cembre.com