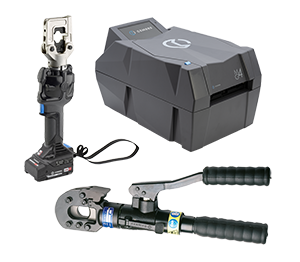

HT120 电池驱动液压压接机

油性,120 kN,开式 C 型头凿岩机,适用于最大 400 mmQ 的电气连接器

Gallery

HT120

电池驱动液压压接机

油性,120 kN,开式 C 型头凿岩机,适用于最大 400 mmQ 的电气连接器

Features

额定压缩力

120 kN

压接段范围

10 ÷ 400 mm²

压力控制系统

max pressure valve

泄压

手动

管头形状

C

动力供应

manual labor

作业净重

9.5 kg

方面

490x156x76 mm

最大尺寸

490x370x76 mm

最小包装单元

1 PCE

标准包装单位

1 PCE

海关编码

84678900

Does your Cembre Product need maintenance?

Fill in the form and follow the instructions to request the maintenance service for your product

Follow us

Subscribe to CEMBRE newsletter and stay tuned

Thank you, your request has been send successfully

You'll be contact soon by our commercial staff

Print label service

Fill in the form and follow the instructions to request the label print service

Thank you, your request has been send successfully

You'll be contact soon by our commercial staff

Does your Cembre Product need maintenance?

Fill in the form and follow the instructions to request the maintenance service for your product

Your maintenance request has been sent successfully

The next steps to complete the maintenance request:

- Print the form

- Send the package to your chosen CEMBRE retailer

Important: Do not insert batteries for safety reasons. Remember to include all accessories

View more

View more

products ()

news ()

corporate ()

results

for

results

for

No results

Can't find results with these keywords

View Cembre group website

cembre.com

Look at products catalog

products.cembre.com

Log into Cembre group reserved area

my.cembre.com