RHC131 HYDRAULIC CRIMPING HEAD

HYDRAULIC CRIMPING HEAD, 130kN, OPEN C-HEAD, FOR ELECTRICAL CONNECTORS UP TO 400 MM2

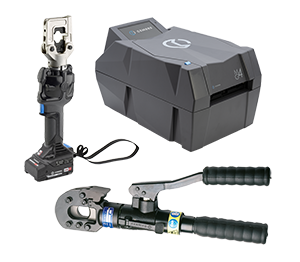

Gallery

RHC131

HYDRAULIC CRIMPING HEAD

HYDRAULIC CRIMPING HEAD, 130kN, OPEN C-HEAD, FOR ELECTRICAL CONNECTORS UP TO 400 MM2

Certifications & approvals

-

CE

CE -

UKCA

UKCA

Description

The RHC131 hydraulic head is suitable for installing crimping electrical connectors on conductors up to 400 mm2. It adopts the standard die set compatible with other 130 kN tools and heads.

The head is open and comes complete with a male quick-release coupling with automatic locking.

For its operation, it is necessary to combine it with a hydraulic pump with a maximum working pressure of 700 bar.

Read all

Close

Features

Nominal crimping force

130 kN

Range of operating temperature

-15 ÷ 50 °C

Crimping section range

10 ÷ 400 mm²

Crimping geometry

hexagonal; oval; indent; radial

Head shape

C

Dimensions

234x129x76 mm

Unit in minimal packaging

1 PCE

Unit in standard packaging

1 PCE

Customs code

84679900

Does your Cembre Product need maintenance?

Fill in the form and follow the instructions to request the maintenance service for your product

Follow us

Subscribe to CEMBRE newsletter and stay tuned

Thank you, your request has been send successfully

You'll be contact soon by our commercial staff

Print label service

Fill in the form and follow the instructions to request the label print service

Thank you, your request has been send successfully

You'll be contact soon by our commercial staff

Does your Cembre Product need maintenance?

Fill in the form and follow the instructions to request the maintenance service for your product

Your maintenance request has been sent successfully

The next steps to complete the maintenance request:

- Print the form

- Send the package to your chosen CEMBRE retailer

Important: Do not insert batteries for safety reasons. Remember to include all accessories