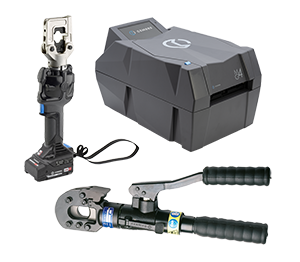

EPB-1N BANKPRESSE

TISCHPRESSE, ELEKTROHYDRAULIK, AUTOMATISCHES ABISOLIEREN/CRIMPEN FÜR ISOLIERTE ADERENDHÜLSEN, VON 0.5 BIS 1.5 mm²

Galerie

EPB-1N

BANKPRESSE

TISCHPRESSE, ELEKTROHYDRAULIK, AUTOMATISCHES ABISOLIEREN/CRIMPEN FÜR ISOLIERTE ADERENDHÜLSEN, VON 0.5 BIS 1.5 mm²

Zertifizierungen & Zulassungen

-

CE

CE

Description

Die elektropneumatische Presse EPB-1N ist die ideale Wahl für das Abisolieren von Leitern und das Komprimieren und Crimpen von vorisolierten Schläuchen mit Querschnitten von 0,5 mm2 bis 1,5 mm2 und Aderendhülsenlängen von 6, 8, 10 und 12 mm.

Dank des elektrisch angetriebenen Vibrationssystems mit Steuerung der Ladegeschwindigkeit führt die Presse Abisolier-, Press- und Crimpvorgänge schnell und einfach aus.

Der modulare Aufbau der Maschine und die automatische Einstellung aller Arbeitsparameter durch den schnellen Wechsel der Einsätze garantieren eine hohe Zuverlässigkeit der Presse.

Alle lesen

Schließen

Merkmale

Bereich der Crimpabschnitte

0.5 ÷ 4 mm²

Komprimierungs-Geometrie

Trapez

Nettogewicht im Betrieb

29 kg

Maße

490x390x240 mm

Mindestverpackungseinheiten

1 PCE

Standardverpackung

1 PCE

Zollcode

84798100

Muss Ihr Produkt von CEMBRE gewartet werden?

Füllen Sie das Formular aus und folgen Sie den Anweisungen, um den Wartungsservice für Ihr Produkt anzufordern

Folgen Sie uns

Abonnieren Sie den CEMBRE-Newsletter, damit wir Sie stets auf dem Laufenden halten können

Vielen Dank! Ihre Nachricht wurde erfolgreich versendet

Die Mitarbeiter unserer Vertriebsabteilung werden sich in Kürze mit Ihnen in Verbindung setzen

Etikettendruckservice

Bitte füllen Sie das Formular aus und folgen Sie den Anweisungen, um unseren Etikettendruckservice zu nutzen.

Vielen Dank! Ihre Nachricht wurde erfolgreich versendet

Die Mitarbeiter unserer Vertriebsabteilung werden sich in Kürze mit Ihnen in Verbindung setzen

Muss Ihr Produkt von CEMBRE gewartet werden?

Füllen Sie das Formular aus und folgen Sie den Anweisungen, um den Wartungsservice für Ihr Produkt anzufordern

Ihr Wartungsantrag wurde erfolgreich abgeschickt.

Nächste Schritte zum Ausfüllen des Instandhaltungsantrags:

- Formular ausdrucken

- Senden Sie das Paket an den von Ihnen ausgewählten CEMBRE-Händler.

Wichtig! Legen Sie aus Sicherheitsgründen keine Akkus bei. Vergessen Sie nicht, alle Zubehörteile beizulegen.