CCS16.11-M6

RING TERMINAL, FOR COPPER CONDUCTORS, SCREW 6mm SECTION 16mmq

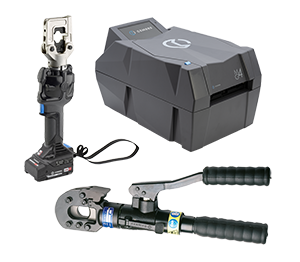

Gallery

CCS16.11-M6

RING TERMINAL, FOR COPPER CONDUCTORS, SCREW 6mm SECTION 16mmq

Features

Minimum operating temperature

-50 °C

Maximum operating temperature

150 °C

Number of holes on the palm

1

Easy insertion input

Yes

Surface treatment

tin plating

Crimping geometry

hexagonal

Range of cable cross section

16 mm²

Conductor body material

Rame elettrolitico con purezza superiore al 99,95%

Annealing

Yes

Screw diameter

M6

Eyelet diameter

6.4 mm

Palm width

15 mm

Centre distance between the palm hole and the outer edge of the eyelet

7 mm

Centre distance between the palm hole and the transition point

8 mm

Centre distance between the palm hole and the outer edge of the barrel

40.5 mm

Tightening torque(8.8 GRADE SCREW)

7 Nm

Tightening torque(HIGH CONDUCTIVITY SCREW)

5 Nm

Total length

47.5 mm

Barrel length(CONDUCTOR)

12.5 mm

Barrel length(INSULATION)

7.5 mm

Barrel length

22 mm

Inner diameter of the barrel(CONDUCTOR)

6 mm

Inner diameter of the barrel(INSULATION)

11 mm

Cable stripping length

14 mm

Outer diameter of barrel(CONDUCTOR)

10 mm

Outer diameter of barrel(INSULATION)

12.3 mm

Unit in minimal packaging

50 PCE

Unit in standard packaging

150 PCE

Customs code

85369010

ROHS compliant

Yes

Reference standard

;

Does your Cembre Product need maintenance?

Fill in the form and follow the instructions to request the maintenance service for your product

Follow us

Subscribe to CEMBRE newsletter and stay tuned

Thank you, your request has been send successfully

You'll be contact soon by our commercial staff

Print label service

Fill in the form and follow the instructions to request the label print service

Thank you, your request has been send successfully

You'll be contact soon by our commercial staff

Does your Cembre Product need maintenance?

Fill in the form and follow the instructions to request the maintenance service for your product

Your maintenance request has been sent successfully

The next steps to complete the maintenance request:

- Print the form

- Send the package to your chosen CEMBRE retailer

Important: Do not insert batteries for safety reasons. Remember to include all accessories